Attaching the Standard Wellhead

Depth Discrete Groundwater Monitoring

Reduce Costs and Field Time

Step 21) Attach the Wellhead

Note:

The Solinst Tag Line, (Model 103), is recommended for accurate sand and bentonite placement.

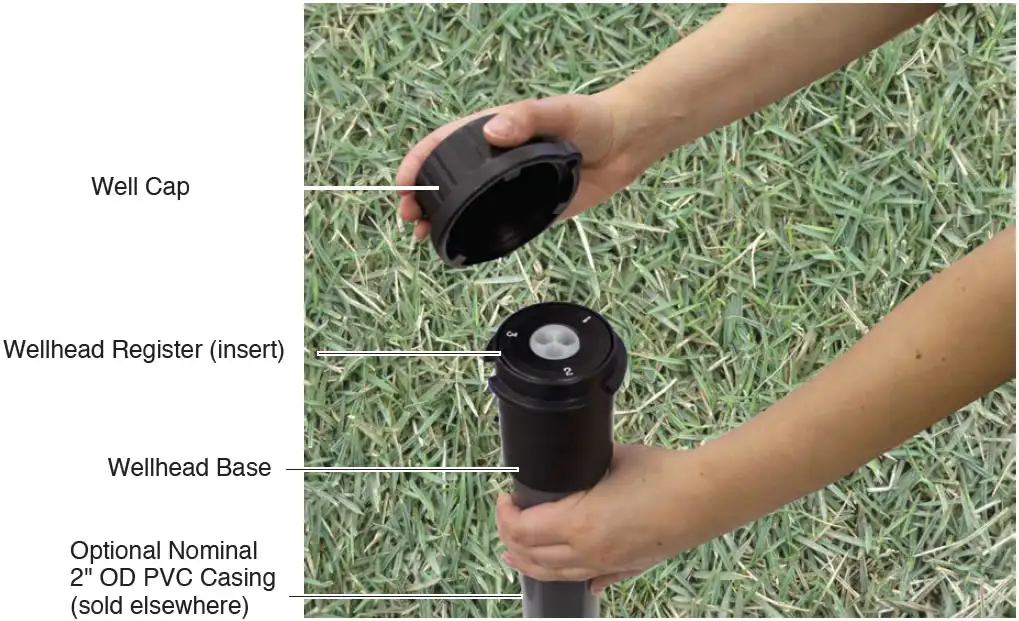

Figure 21 – Bring The Pvc Pipe Up So The CMT Multilevel System Register Seats In The Wellhead Base

After the well has been built, cut the CMT tubing to the final elevation. You may choose to finish your CMT installation above ground surface. If so, you can leave the CMT stick-up as is and install the standard wellhead register or “house” the CMT inside a cut length of 2″ dia. PVC riser pipe (not supplied).

If housing in a PVC pipe, first slide the PVC pipe over the CMT stick-up, and push below the final elevation of the CMT. Slide the wellhead base over the tubing and onto the PVC pipe. The wellhead base provides a tight friction fit on the PVC pipe.

Locate Channel 1 and slide the wellhead register over the tubing, flush with the end. Align the stamped number one on the register with the Channel 1 identifier marking on the outside of the tubing. Secure the wellhead register to the CMT tubing by tightening the hex screw on the side of the register using a 1/8″ Allen Key. Bring the PVC pipe up so the register seats in the wellhead base (Figure 21). Grout or cement the PVC pipe in place.